With the largest 3D printing capacity of any nonprofit in the state of Wisconsin, Concordia University has sprung into action to fill the production gap of one of the most necessary medical supplies for professionals combatting the novel coronavirus.

COVID-19 has caused a global shortage of the heavy-duty N95 respirator masks utilized by healthcare workers to avoid contamination. As manufacturers worldwide scramble to find innovative ways to maximize production, Concordia, along with regional partners, is doing its part to serve its hometown community.

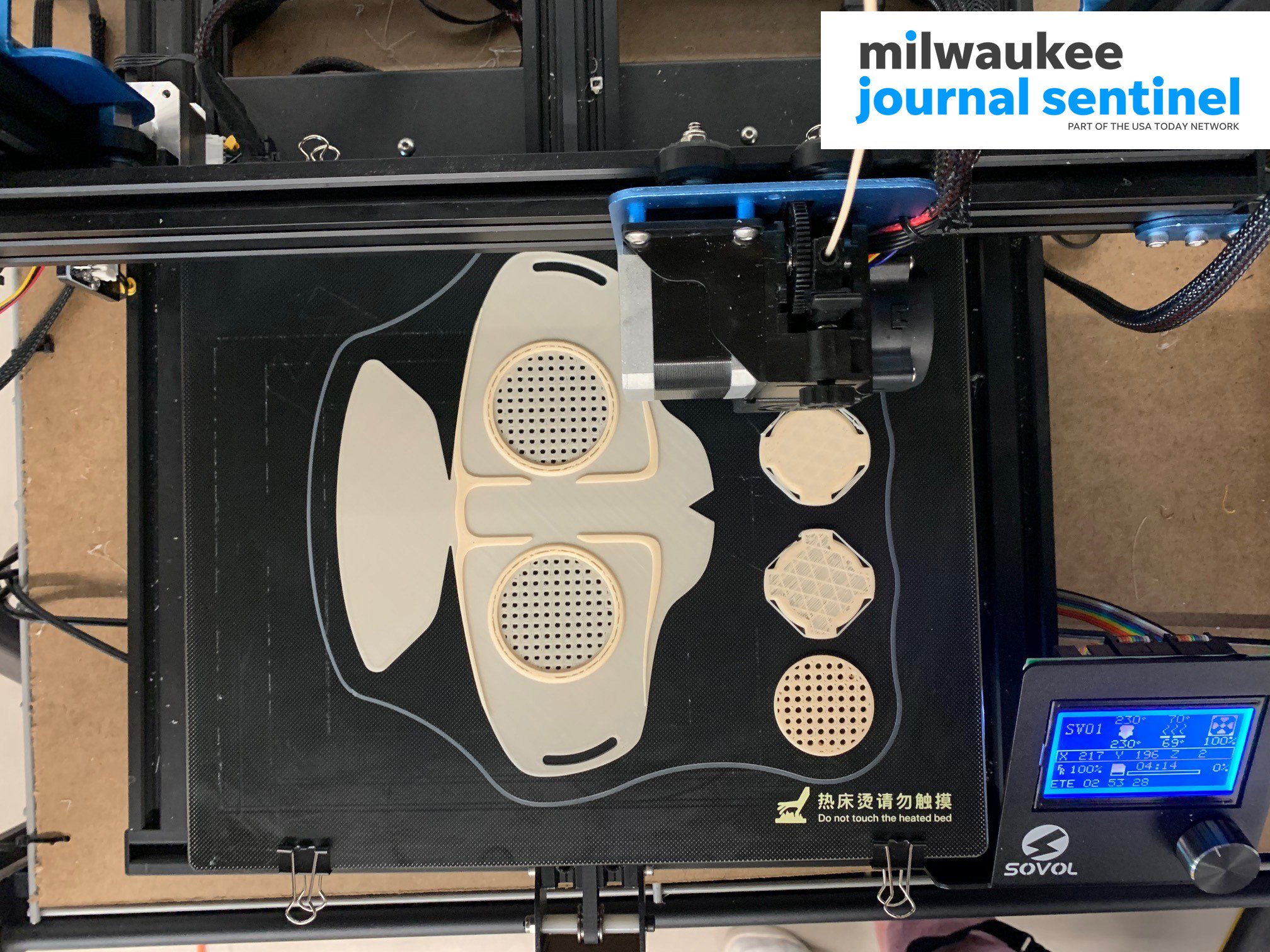

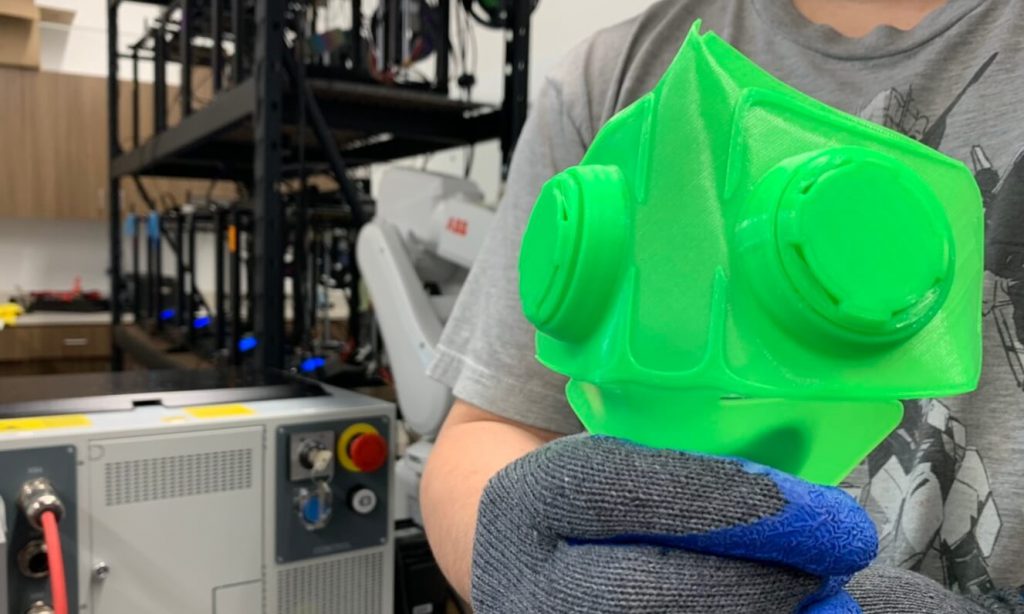

Leaning on direct input from area medical professionals on the front lines, Concordia has teamed up with UWM’s Prototyping Center to identify an ideal prototype of an N95-modeled mask to be printed. What they came up with is not certified by the National Institute of Occupational Safety and Health (NIOSH)—the direness of the concern at hand does not allow time for that. Nevertheless, it’s just what the doctor ordered.

“We’re hearing from the medical community that they need the masks, and they need them now,” said Dr. Dan Sem, dean of Concordia’s Batterman School of Business. “Our goal is to get these N95 prototypes produced and delivered as quickly as possible to keep the medical professionals using them as safe as possible. The internal experts at the health care institutions are aware of the certification limitation and are doing their own assessments, but they need the masks now.”

While the typical university owns at most a handful of 3D printers, Concordia’s brand-new Makerspace Lab boasts 30 machines. Each one is currently engaged in printing prototypes all day long. Within a 24-hour span, Concordia’s Makerspace has the capacity to print upwards of 70 respirator masks under one design.

That will add up to around 1,000 respirator masks within the two weeks that two local manufacturers estimate it will take them to produce a large-scale solution. Those manufacturers are HUSCO International, a global automotive manufacturer based in Waukesha, and the Fortune 1000 manufacturer Briggs and Stratton, which is headquartered in Wauwatosa.

Sem, who is a seasoned entrepreneur in the chemical and pharmaceutical fields, was invited to present Concordia’s prototype to a team of physicians at Children’s Hospital, as well as leaders within HUSCO and other area organizations.

Concordia’s Dr. Ken Harris, who previous served as a lieutenant with the Milwaukee Police Department, is leading the charge to rally law enforcement within the Milwaukee Police Department to safely deliver the products to Children’s Hospital and other Wisconsin medical organizations once they are completed.

Do you have a 3D printer?

Do you have a 3D printer?

Update 4.27.2020: While there has been a positive response to the at home filter assembly, we are still lacking on the gasket pouring side and have changed the schedule out of necessity so it might be compatible for more people. https://www.cuw.edu/makerspace

Times need to be separated, so the silicone has a chance to set enough in the morning to allow for a second pouring before 1 p.m. We are proposing a second shift from 4-6 p.m. Monday-Friday to remove the morning batch and pour another batch to set up overnight. The morning shift will change to roughly 9-11 a.m. In approximately 3 weeks, an external company will be able to mass produce the gaskets, so this is temporary, and no special skills are required.

Update 4.6.2020: Concordia has reached its capacity for crowdsourced 3D printers. We are no longer accepting printer registrations. If you would like to access the 3D print file for your individual purposes, please click here.

One way to address the respiratory mask shortage is to crowdsource 3D printers. As Concordia and its regional partners work together to fill the production gap to protect the state’s valued medical workers and first responders, Concordia University Wisconsin asks organizations with 3D printer(s) to share your information.

Sharing your information does not commit you to participation in this project, it’s simply your way to request more details so that you can decide if getting involved is the right fit for your organization.

Concordia University Wisconsin will not share your information with any third party and will only use your information for the specific purposes of the COVID-19 Respirator Mask Production Project.

NOTE: We ask for the street address of your printer location because the Milwaukee Police Department will be assisting us in the pick-up and delivery of printed respirator masks.

Media Placements

Concordia’s efforts to 3D print respirator masks received attention from several local news stations. Click on the images below to check out their segments.